Compound miter saw purchasing advice: how to choose the right product

- The most important facts in brief

- With cross-cut saws, craftsmen can first and foremost “cut”, i.e. shorten.

- They are ideal for straight cuts that are made in a vertical direction.

- They are often combination saws that combine cross-cut, mitre and pull saws.

- The multifunctional models are capable of cutting a wide variety of angles and boards of different widths.

Kappsägen – unentbehrlich für die Holzbearbeitung

A crosscut saw is an electrically driven machine that is primarily used in wood processing. The crosscut saw is an important tool in that it can be used to cut wood in a vertical direction. This makes it possible to cut pieces of wood lengthwise to the desired size. Without cross-cut saws, wood processing would hardly be conceivable.

They usually have a circular saw blade fitted to the top of a frame. The saw blade is fed from above to the piece of wood to be cut and cuts straight through it from top to bottom.

Overview of typical applications

A cross-cut saw can be used to shorten pieces of wood of different widths and formats. Typically, cross-cut saws are used for cutting wooden panels or shortening laminate and parquet flooring. They are also ideal for making picture frames or frames for windows and doors.

The different types

Since cross-cutting wood is of enormous importance in various situations, different types of cross-cut saws have become established over the course of time. We present them in the following overview.

The under-table cross-cut saw

An under-table cross-cut saw is a large cross-cut saw that is permanently mounted on a table. The circular saw blade cuts clamped workpieces lengthwise. For easier operation, roller conveyors are attached to the machine. This design is especially intended for professional use. The under-table cross-cut saw is therefore mainly found in trade and industry, for example in sawmills, in carpentry and joinery businesses as well as in packaging departments of industrial companies of various kinds. The under-table cross-cut saw is very common and it is hard to imagine the commercial sector without it.

Pro points

- High precision

- Very powerful

- Straight cuts

Drawbacks

- Only suitable for commercial use

- Not mobile

The cross-cut and pull saw

In contrast to the crosscut saw, the crosscut and pull saw is not only suitable for making cuts in the vertical direction, but also in the horizontal direction. It is therefore able to cut wide beams narrower. In this way, the crosscut and pull saw can be used to make the most important straight cuts in both directions. However, with the pull function of the pull and crosscut saw, this is not possible with boards of any length.

Pro points

- Variable cutting direction

- High precision

- Straight cuts

Drawbacks

- Cuts in horizontal direction only possible to a limited extent

- Not mobile applicable

The mitre crosscut saw

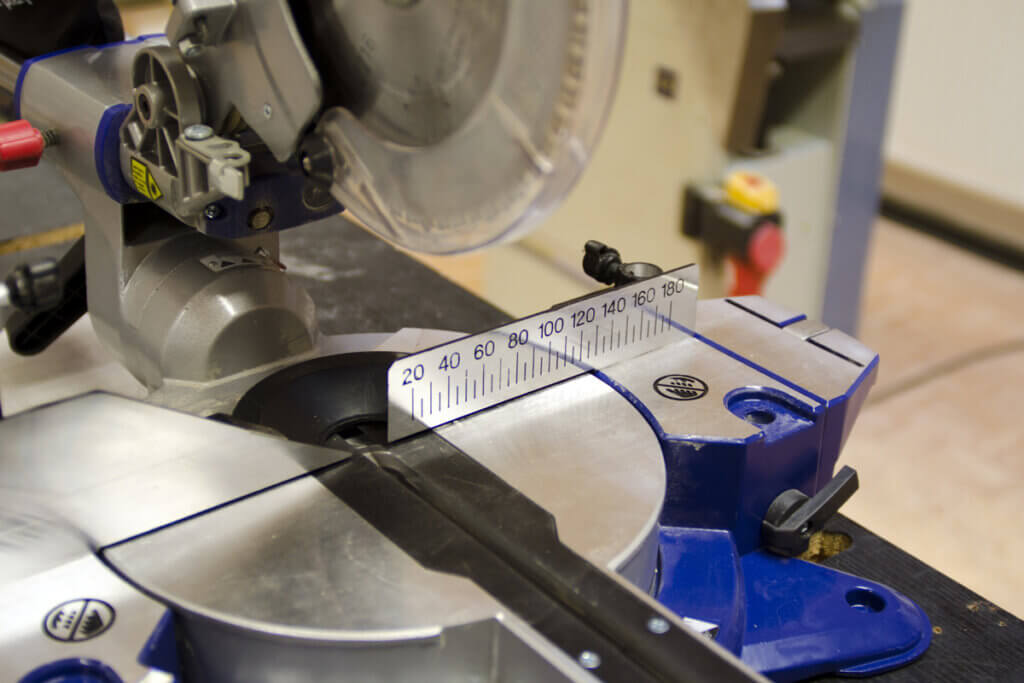

A mitre cross-cut saw is not only suitable for straight cross-cutting of boards, but it also allows mitre cuts. In this way, boards can be shortened and adjusted at different angles. The desired angle can usually be set with a knob. On traditional models, the adjustment can also be made mechanically. The angles are essential for numerous constructions made of wood, such as door frames or windows.

Pro points

- Various cuts can be made

- Angle suitable for many constructions made of wood

Drawbacks

- Not mobile applicable

The cross-cut, mitre and table saw

This type of saw, as the name suggests, is a combination of the chop saw and mitre saw, to which the function of a table saw is added. To activate this function, users must tilt the table 180 degrees. However, safety gaps were frequently criticised in view of the conversion. Such machines, which have only been in production since the 1990s, have therefore not been newly manufactured since the 2000s.

Pro points

- Combines the functions of the crosscut, mitre and table saw

Drawbacks

- Weaknesses in handling due to complicated conversion

- Safety deficiencies

The radial arm circular saw

The radial arm circular saw is a cross-cut saw with a special design. It is named after the cantilevered arm on which the saw is moved with the help of roller bearings or rollers. The saw can be turned 90 degrees and also swivelled. It is also possible to raise the arm of the saw. This makes the radial arm circular saw similar to a bench drill. In addition, users can easily cut grooves in a workpiece with this design thanks to the movable arm.

Pro points

- Numerous options for cutting wood to size

- Intelligent handling

- High precision

Drawbacks

- Not mobile applicable

- High price

The crosscut saw for round timber

Although most cross-cut saws are designed primarily to cut boards, there are also models available for round timber. These are used to cut round timber so that its curvature is minimised.

Pro points

- Straight cuts for round timber

- High precision

Drawbacks

- Few application possibilities

The package crosscut saw

A package crosscut saw is a crosscut saw that is exclusively designed to crosscut boards stacked in a package. A package saw is therefore only used in very specific situations. They are often found in sawmills. Its use is limited because the package crosscut saw cuts too uncleanly for targeted cuts on individual boards.

Pro points

- Powerful

- Shorten whole packages at once

Drawbacks

- Few application possibilities

- Unclean cuts

The cross-cut systems

Cross-cut systems are cross-cut saws designed for use in industry. The automatic machines are controlled and programmed electronically via a computer. Thus, the computers are able to measure the input length or calculate defects. From the measurements and those of the desired finished lengths, the automatic machine independently calculates how best to crosscut the wood in order to work as efficiently as possible and produce the largest possible quantity of pieces of wood.

Pro points

- Very efficient

- Highly automated processing

Drawbacks

- Exclusively for industrial production

What matters when buying

To find the right model for you, other factors such as performance, stability and range of functions are decisive in addition to the cutting depth and width. In addition, the equipment and handling also play a role in the purchase decision.

The cutting depth and width

The cutting depth or cutting width factor determines how thick and how wide the workpiece to be cut can be. The saw achieves the greatest values at a cutting angle of 90 degrees. The width in particular can vary greatly among cross-cut saws. While some manufacturers only specify 120 millimetres, other saws reach 300 millimetres or more. In terms of depth, around 70 millimetres is standard. However, there are also models with a cutting depth of only 60 or over 90 millimetres.

The power

The power of the crosscut saw depends primarily on the wattage. However, prospective buyers should also consider how many revolutions per minute the saw can achieve. Experts recommend a power of at least 1,000 watts. For the cutting edge, it is essential to achieve a certain number of revolutions per minute. Otherwise, the quality of the cutting edge can suffer. This is more often the case with harder materials. When idling, the crosscut saw should have at least 3,000 revolutions per minute.

Stability

Cross-cut saws are characterised by the fact that the saw blade is firmly mounted on a frame. Accordingly, it is also important that the frame is stable to ensure not only precise cuts but also safety when working.

The functions

Should the saw only cut narrow boards or also have a mitre and pull function? With the pull function, the function can be extended in that very wide workpieces can also be cut. With the help of the mitre function, it is also possible to make mitre cuts. Therefore, prospective buyers should be aware of which functions they need for woodworking and woodcutting.

The laser and precision tools

A laser can increase the precision of sawing many times over – but only if it is precisely adjusted itself. Users should definitely check this little extra before the warranty expires. Especially if they have an inexperienced hand, it is important to use a well-functioning laser.

Also helping with precision are stop rails and clamping devices. Precise cutting is only possible if these devices are well made. While the stop bar is useful for guiding the saw, the clamping device holds the workpieces firmly in the holder.

Handling and comfort

An ergonomic design can work wonders in terms of comfort. Apart from a practical arrangement of the most important buttons and levers, a good padding of the handles, e.g. soft-grip, can also have a positive effect on comfort during work. To ensure that handling is also practical for the user, the buttons and their functions should be almost self-explanatory and therefore intuitive to use.

Accessories to make work easier

One or two accessories can make working with a chop saw much easier. These include a chip collection bag, an extendable saw table, spare saw blades and various protective accessories such as safety goggles, ear protection and safety clothing.

Catch bag for chips

If you don’t want to disappear in a cloud full of dust and sawdust, use a catch bag as a tool to catch the sawdust before the dirt gets swirled around. However, there are even more effective solutions than a catch bag. Since the catcher bags usually do not actively suck up the dirt, but only catch what is blown towards them, the effectiveness of the catcher bags is not the best. If you work with your crosscut saw very often, you might consider buying an extraction device, such as an industrial hoover.

Extendable saw table

On some cross-cut saws, a frame can be pulled out at the sides. With this stand, it is possible to place longer workpieces on the table without them wobbling or sagging during processing.

Spare saw blades

When sawing, the saw blade is crucial for good results. That is why it should always be sharp. It is therefore worthwhile to always have one or two saw blades in reserve.

Safety goggles, ear protection and safety clothing

When working with a chop saw, it is of immense importance that craftsmen pay attention to their safety. This includes certain accessories such as safety goggles, which protect the eyes from flying sawdust or wood splinters. Sparks are particularly likely to fly when cutting metal.

Hearing protection is also necessary when working with a crosscut saw. If you work often and for a long time with tools that make a lot of noise, you risk permanent hearing damage. It is important that users ensure that they are using hearing protection that meets official standards.

Furthermore, for their own safety, they should make sure that they do not wear loose clothing that could get caught in the saw blade. Scarves, long necklaces or earrings are just as unsuitable as open hair. It is also advisable to wear protective gloves in which the saw can get caught in the event of contact.

Care and use tips

In order to enjoy their tool for as long as possible, craftsmen should pay attention to a few elementary tips concerning the care and use of a cross-cut saw:

- Before starting cleaning and care, users should always switch off the motor and pull out the mains plug. With a battery-powered device, it is important to remove the battery.

- The crosscut saw should be cleaned of sawdust after each use. For particularly fine dust that has settled in the cracks and edges, a compressed air spray is recommended.

- Stubborn dirt can be wiped off with a lint-free, slightly damp cloth.

- To keep the moving parts of the crosscut saw moving well, oil them regularly. However, it is important not to overdo it. A small drop is usually enough.

- Ideally, users should check the screws before each use of the crosscut saw and tighten them if necessary.

1,318 reviews

1,318 reviews