Circular saw purchasing advice: how to choose the right product

- What You Need to Know

- Circular saws are divided into hand-held circular saws, table circular saws, construction circular saws, metal circular saws and cross-cut saws.

- Hand-held circular saws are ideal for stationary use. These compact devices are very suitable for making particularly fine cuts.

- The size of the saw blade is crucial for the quality of the cut. The larger the blade, the thicker the material to be cut can be.

- With powerful circular saws, you can easily cut through harder materials. The motor power is therefore relevant depending on the intended use.

The right circular saw for every application

Circular saws are available in versions for a wide range of applications. This means that you have a suitable model for every task, with which you can reliably get the job done. But regardless of which type of circular saw you use, they all have one thing in common: their characteristic screeching sound. Most people associate this sound with the teeth of a circular saw eating into wood or other material.

Every hobbyist or professional craftsman knows the tension before the first cut. After all, if the saw does not work properly or the saw blade is blunt, this not only costs time but also material; in the worst case, the circular saw itself suffers. Therefore, you should always make sure that you use a functioning tool that meets your requirements. Furthermore, the right way of working is crucial to ensuring that you are satisfied with the result.

What is a circular saw?

Circular saws are saws with circular saw blades that are used to cut up or process a wide variety of workpieces. The material is irrelevant. With the right saw blade, circular saws can cut not only wood, but also metal, plastic or natural stone. However, circular saws are most often used for wood or metal products.

Observe quiet times

Circular saws are very loud. The noise level is usually above the permissible noise limit of 85 decibels. Most circular saws reach over 100 decibels. Especially when doing extensive work, it is important to observe the legal rest periods so as not to disturb your surroundings. Therefore, the use of a circular saw is only permitted between 7 am and 8 pm. From 1 p.m. to 3 p.m., a midday rest period must be observed.

How does a circular saw work?

The circular saw blade is as characteristic of a circular saw as its working noise. There are numerous cutting teeth on the edge of the saw blade that eat into the material to be sawn and cut it up. The saw blade is driven differently depending on the model. In some, it sits directly on a drive shaft, in others it is driven by a belt. However, the actual function is always the same: as soon as the motor is switched on, the saw blade starts to rotate at several thousand revolutions per minute. Now the circular saw can be guided over the workpiece so that the teeth of the saw blade cut the material. With some circular saws, you have the option of regulating the speed of the saw blade in order to slowly approach a workpiece or also to work on delicate materials that may splinter quickly.

A model for every purpose

There are numerous circular saw models whose appearance and functions are designed for different tasks. The most common models include the table circular saw, the hand circular saw, the metal circular saw, the construction circular saw and the chop saw. Hand-held circular saws are also common in private use, while construction and cross-cut circular saws, for example, are much less common as hobby tools.

Circular hand saws

Circular hand saws are very compactly built and therefore very versatile. They are ideal for sawing wood or laminate as well as other thin workpieces. The saw blade is guided by the handle, which is located next to or above the blade’s top guard. The advantage of the hand-held circular saw is its flexibility: the compact design and low weight make it very mobile. You can also choose between battery-powered and corded circular saws.

Some models also have a hoover connection to suck up falling chips and dust directly. The price of a hand-held circular saw is comparatively low, but they are not always suitable for all materials due to lower performance. If you are looking for a hand-held circular saw for special tasks, you should make sure that it is suitable for the intended material. It should not be too thick, as the cutting width for circular hand saws is usually smaller than for other types of circular saws. However, another plus point is the ability to make mitre cuts with at least some models.

Pro points

- Very flexible

- Battery or cord operation possible

- Comparatively cheap

Drawbacks

- Low power

- Small cutting depth

Circular table saws

Table circular saws are designed for stationary use. The saw blade and motor are mounted on a base similar to a workbench. Compared to a hand-held circular saw, they have considerably more power. Since mobility is less important, a larger and more powerful motor is installed. The material to be cut is positioned on the table and guided into the saw blade. So here it is not the saw that comes to the material, but the material to the saw.

Many models have fences or guide rails along which you can guide the material, so that even difficult cuts are easy to make. Due to their design, there are hardly any restrictions on the cutting depth or width of circular table saws. You can even process large workpieces easily. The hoover connection is usually integrated as standard. As a rule, the tables are height-adjustable so that the device can be adapted to the height of the user. Thanks to the solid base, sawing takes place almost without vibrations.

One disadvantage, however, is the lack of mobility. Due to the design and the significantly higher weight, the saws are difficult to move or transport. In addition, although they offer more power, the large saws are considerably more expensive than the small hand saws.

Pro points

- High power

- Large cutting width and depth

- Precise cuts possible

- Height adjustable

- No vibrations when working

Drawbacks

- Very bulky

- High weight

- Comparatively expensive

Metal circular saws

Metal circular saws are primarily designed for workpieces made of metal. A special saw blade with particularly fine teeth is used for this purpose, as this is the only way to cut angle iron or metal rods cleanly. The motor of these circular saws usually runs much slower than that of other models, which means that the number of revolutions is also lower. However, since the work material is harder, this ensures that neither the saw and the saw blade nor the workpiece are damaged. In addition, the low speed results in less flying sparks. Many circular metal saws work in combination with a special cooling fluid that cools the saw blade during longer sawing sessions, thus protecting it from possible damage to the saw and the workpiece.

Construction circular saws

Construction circular saws were developed especially for use on construction sites. They are much more robust and often have a riving knife that acts as a guard. The wedge is uniformly wide and usually has a triangular or scythe-shaped cross-section. It prevents the saw blade from jamming in the kerf. Some models also have a cross-cut fence or mitre fence that can be used to cut the workpiece at special angles. This allows you to make the cut quickly and in the desired shape. You will find high-quality construction circular saws mainly from market-leading manufacturers such as Einhell, Bosch, Atika or Metabo.

Chop saws

Cross-cut saws offer the possibility to change the mitre and thus the angle of a workpiece. For this reason, cross-cut saws are also called mitre saws. A mitre is the corner joint of two workpieces that meet at an angle. The saw blade is on an arm that can be pressed down. The workpiece rests on the stand, which also serves as a support surface.

Since the saws are primarily suitable for mitre cuts, they are mainly used in interior finishing when laying wooden floors. The devices are light and compactly built so that they can be easily transported from one place to another.

What matters when buying

Due to the variety of models, the features and functions of circular saws differ. When buying, you should therefore pay attention to the following criteria and always consider which materials you want to work on with the saw. Important purchase criteria are the saw blade used and the number of saw teeth. The cutting depth and the speed can also be relevant depending on the intended use. Last but not least, you should consider the operating variant, the motor power and the weight.

Saw blade

The saw blade is the most important component of a circular saw. Its diameter determines the cutting width and cutting depth. Therefore, make sure that the diameter of the saw blade fits your planned work and is compatible with your machine. As a rule, the size of a saw blade is indicated with two values. For example, “200 mm x 30 mm” means that the diameter of the entire saw blade is 200 millimetres and the diameter of the hole in the centre is 30 millimetres.

Cutting width

The cutting width describes the width that the saw blade needs for a clean cut. The wider the saw blade, the more work material you effectively cut away. Pay attention to this when you draw a mark. The cutting width of the saw blade of hand-held circular saws is usually 2 to 4 millimetres. Circular table saws, on the other hand, have larger cutting widths of 60 to 600 millimetres.

Cutting depth

The depth of cut indicates how thick a board can be. So if you want to saw 4 centimetres deep into a workpiece, the cutting depth must be at least 40 millimetres. High-quality circular hand saws, for example, achieve cutting depths of up to 70 millimetres. Simpler models, on the other hand, usually only have a cutting depth of about 50 millimetres. Some models offer the option of fitting saw blades of different sizes. This makes the depth of cut variable.

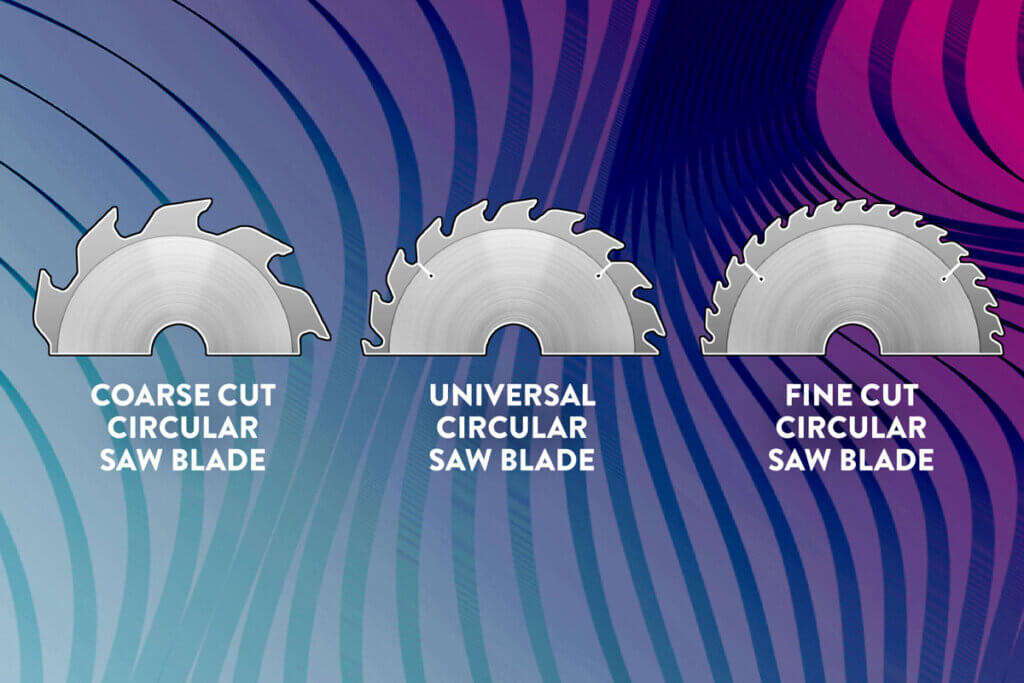

Saw teeth

A blade with a few rather coarse saw teeth is ideal for lengthwise cuts. Models with 10 to 50 teeth are recommended here. If you want to make cross-sections, on the other hand, a blade with many small saw teeth is recommended. For this purpose, you can get saw blades with up to 300 saw teeth. For materials that can tear out very easily, you should also use a saw blade with very fine teeth.

Speed

The speed indication of the circular saw provides information about the speed of the saw blade once the machine is switched on. For some materials, a slower speed is important to achieve a clean cut. The speed of metal circular saws is usually much lower in order to keep sparks to a minimum. With some models it is also possible to adjust the speed individually. These machines are particularly flexible and intended for a wider range of tasks.

Engine power

The engine power of a circular saw is a direct indication of its performance. Too little motor power can be a problem, for example, with hardwood or other hard materials. Good circular saws should therefore have a motor power of at least 1,200 watts. Larger types of saws such as circular table saws usually have very powerful motors with 2,000 watts or more.

Cord or battery

Circular saws are available with either a rechargeable battery or a cable. Battery-powered circular saws can be used more flexibly than corded models. In addition, you don’t have to constantly keep an eye on the cable and make sure it doesn’t get in your way while you’re working. They can also be used in the garden or on construction sites when there is no power socket nearby. However, the power of battery-powered tools is limited.

Models that are plugged into a wall socket have enough power to cut up harder materials without problems. For this reason, the larger circular saw types are usually only offered with a cord.

Weight

The weight of a circular saw has an impact on its flexibility and mobility; it plays a decisive role especially for hand-held circular saws. A table saw weighing 20 to 60 kilograms is placed in one place and used there. Hand-held circular saws, on the other hand, should be easy to handle. Too much weight makes the work more difficult and the result may be unclean. That is why hand-held circular saws usually weigh only about 3 to 5 kilograms.

Safety precautions

Before working with a circular saw, make sure you protect yourself as best you can. This includes first checking the circular saw. It must be fully functional and should not have any damaged or wobbly parts. Circular saws are equipped with various precautions to keep the risk of injury low. These include, for example, the riving knife and a saw blade cover.

In addition, it is advisable to put on protective equipment. Make sure that your clothing is not too loose. Also take off chains and other loose objects. Long hair should ideally be tied up. Last but not least, wear safety goggles and ear protection to protect your eyes from sparks and your ears from the noise.

3,403 reviews

3,403 reviews