Power generator purchasing advice: how to choose the right product

- What You Need to Know

- A power generator can be used to bridge power outages. In principle, however, it can also be used simply as a flexible source of electricity.

- Power generators are available with different drive technologies: Petrol, diesel, gas or accumulators

- Diesel-powered gensets are usually the most powerful.

- In order to be able to choose a suitable power generator, the areas of application and the required power must be known. A power buffer of 20 to 30 percent should always be taken into account.

- Regular maintenance and cleaning are very important to ensure trouble-free operation in an emergency. A test run should be carried out every two months at the latest.

What is a power generator?

With an emergency power generator, also called an emergency generator, power failures can be easily bridged. These small power plants can be vital: in the event of a power failure in a hospital, for example, they ensure that the lighting and machinery continue to function. In a nuclear power plant, they guarantee that the fuel rods are cooled even if the power supply fails. However, such a genset is not only designed for emergencies; it can also contribute to a flexible power supply.

Power generators are a must

Those who think that power generators are of little importance should think back to 4 November 2006. At that time, almost 10 million households in Europe were affected by a blackout that lasted two hours in some places. In the nuclear disaster in Fukushima, power generators were flooded by a devastating tsunami and three reactors suffered catastrophic meltdowns.

Emergency power generators are island-connected machines that produce electricity. Even though the name suggests it, such a power generator is not just for emergencies: Wherever electricity is needed for work but no power source is available, an emergency power generator can be used as a practical solution.

How does a power generator work?

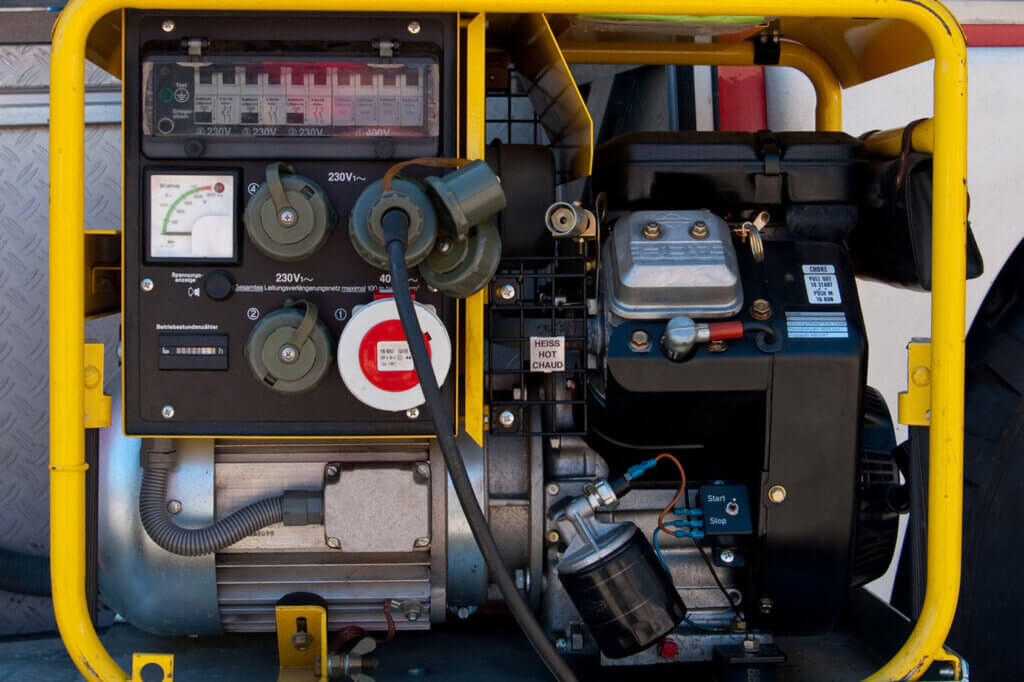

A power generator is like a mini power station. The main components are an internal combustion engine and the generator connected to it. Diesel, petrol or gas can be used to drive the combustion engine. Combustion produces mechanical energy, which is passed on to the generator. The generator converts it into electricity. The power output or size of the power generator can vary greatly; the market offers a wide selection.

Basically, a distinction must be made between stationary and mobile gensets for power generation. The latter are characterised by their compact design. Smaller power generators are usually portable and ready for use in just a few steps. Larger, stationary models, on the other hand, can achieve a high level of performance, for example, to reliably supply a certain part of a clinic with electricity after a blackout.

The following basic models are available:

- Models with combustion engine (petrol or diesel)

- Gas-powered generators

- Inverter generators

Models with combustion engine (petrol or diesel)

A diesel-powered power generator is usually more powerful than petrol-powered models. The latter are more suitable for small-scale private use (for example, for the music system at a party). The higher the power rating, the more devices can be connected to such a generator at the same time.

Gas-powered generators

Gas is an alternative to diesel or petrol. The construction and mode of operation of the corresponding power generators are similar to petrol or diesel models; however, gas-powered generators offer less power than diesel-powered generators.

Inverter generator

This is a special inverter that converts the generated electricity into a final product that is as sinusoidal as possible. Such a generator is able to convert direct current into alternating current and produce a constant alternating voltage. Such a voltage is necessary for the operation of very sensitive electrical appliances. If you need a very high power quality with regard to use, you should opt for an inverter generator. A high-quality model is able to generate a harmonic voltage that reaches mains power quality. It should be borne in mind that the power quality affects the service life of the connected devices. For example, if you want to watch a football match with a mobile power generator, you will be able to achieve the best possible picture quality with an inverter.

Saving energy

With inverter technology, the generator and the integrated combustion engine work independently of each other. An advantage is the option to adjust the engine speed downwards in partial load mode to the amount of energy required. In this mode, such a power generator can operate more quietly and with lower fuel consumption.

Gas turbines for supplying larger plants

In the industrial sector, powerful power generation solutions are often required. The emergency generator models described above are only suitable to a limited extent. Gas turbines are often required to drive the generator.

Power generators with batteries

Another variant are power generators that work with rechargeable batteries and are connected to an inverter. Such solutions are power generators whose operating time is limited. With combustion engines, petrol or diesel can always be refilled. If you want to bridge even long interruptions in the public power grid, you may be taking a risk in the case of a battery-operated model with regard to security of supply.

Combination of motor and battery operation

Such powerful variants are also available. As a rule, the batteries initially take over operation. If it is only a short breakdown, battery operation should be sufficient. For longer periods, the internal combustion engines can start up at a later time. Battery operation can also be considered as a further level of safety if the supply of electricity must be ensured in any case.

The advantages and disadvantages of power generators at a glance:

Pro points

- Safe maintenance of power supply in the event of a blackout

- Flexible solutions for every application: from mobile to powerful stationary models

- With a special inverter genset you get high power quality

Drawbacks

- Relatively high noise level during operation

- Most power generators rely on fossil fuels

How do I find the right model?

To find a suitable power generator, you need to be clear about the area of use and the associated power requirements. For private use (for example, camping), a small mobile version is usually sufficient. In the commercial sector, a large, stationary unit should be chosen for a reliable power supply.

Selecting the right power level

It is easy to determine the power consumption of connected devices. It is therefore quickly clear what the minimum power rating of such a genset must be. It is advisable to have buffers for the power capacities within a range of 20 to 30 percent. In this case, the power supply remains secure even if another unit is connected. And such a buffer is also distributive in the long term, because with it the genset does not always have to be used at maximum power. Constant use at maximum power can have a negative effect on the service life of the motor.

Choosing the right engine

Prospective buyers can choose between diesel, petrol, gas engines, battery-powered models and inverter technology. The choice of the right engine depends directly on the application: the more power a unit has to deliver, the more likely it is to be petrol or diesel. For short-term use or emergency operation, gensets with batteries can be an appropriate solution.

Power generators with inverter technology offer the most flexibility. They generate high-quality electricity that is an equivalent alternative to mains electricity. If the quality of the electricity plays a decisive role, then the choice should go to a power generator with inverter technology.

Noise level

A power generator produces a certain level of noise during operation. This is indicated in decibels, so that the available models can also be compared in this respect. If a large unit is installed in a separate room, this aspect does not play a decisive role in the selection. However, if the unit is in the immediate vicinity of the user, for example when camping, it should be a rather quiet model.

In the meantime, however, manufacturers have equipped their emergency generators with special soundproofing devices, so that relatively quiet operation can be assumed. Inverter emergency generators are considered to be a particularly quiet variant.

If it is purely a backup for emergencies, a high noise level will not really be an important criterion. For orientation: Low noise levels range between 83 and 92 decibels. Typical noise levels are between 95 and 100 decibels.

Power output quality

Connected devices suffer in the long run from a supply of “bad” power. Those who do not opt for inverter technology should check whether the power and voltage can be regulated. In addition to the product description, test reports also provide important information.

Consider follow-up costs

The price usually plays a significant role in the purchase of a power generator. With regular use, the energy consumption may cause high follow-up costs. In this context, maintenance should also be taken into account. Low-maintenance units prove to be more cost-saving in the long run.

Size, mobility and handling

If an emergency generator frequently changes its place of use, size and weight play an important role. Especially for mobile use in leisure time, the weight should be kept within limits. Otherwise, even transporting it to the place of use can become an ordeal. In this context, it should be pointed out that the majority of converter designs today are of lightweight construction. A handle or a trolley function make it easy to transport larger and heavier versions.

Special features for stationary use

In hospitals, the installation of emergency power generators is obligatory; after all, the operation of the machines located in the hospital and the possibly vital lighting must be ensured even in the event of power failures.

But also in the industrial sector, power generators are often used for safety reasons in order to prevent expensive downtimes. The more complex and demanding the application, the more safety buffers the power generator should have. Depending on the area of use, the performance requirements to be met should be carefully examined.

What you should pay attention to during use

The maintenance of a power generator is of great importance, because the device must function reliably in an emergency. Many areas of use involve emergency situations, so nothing should be left to chance when it comes to regular maintenance and checks.

It is important to read the operating instructions carefully and to follow all the instructions they contain. It should be noted, for example, that the engine must not be operated without a sufficient amount of oil. Before starting the engine for the first time, make sure that there is enough oil. Too low an oil level can have a very negative effect on the service life of the power generator. Depending on the model and manufacturer, the specifications regarding the oil change are different. Experience shows that this is necessary after 75 to 150 hours of operation.

Checking the spark plugs and test runs

If the genset for emergency power generation is not used regularly, test runs should be carried out. This way, it can be checked whether the unit starts reliably. Experts recommend running an emergency generator for half an hour every two months, with a load of between 30 and 50 percent.

Spark plugs play a key role in smooth operation. These should be checked regularly and replaced if necessary. In emergencies, a genset is worthless if the spark plugs fail.

Cleaning and site requirements

To ensure reliable operation, the power generator should be regularly cleaned of dust and other debris. Ideally, one should choose a location where harmful influences can be largely excluded. Too much dust can also have a negative influence on the cooling capacity.

The location must be chosen very carefully. First and foremost, it is important that it is dry. Moisture can lead to damage or short circuits. In the long run, corrosion can become a problem for the stability of the entire construction.

Maintaining a power generator yourself? Complex technology requires know-how!

With very many models, the maintenance work is complex, so it must be carried out by an experienced specialist. In addition, failure to follow the manufacturer’s instructions can invalidate the warranty. Depending on the size and area of use, maintenance should therefore be carried out by an experienced specialist if necessary. It is essential to observe the maintenance intervals specified by the manufacturers, as these are based on experience and technical data.

785 reviews

785 reviews