Cordless impact driver purchasing advice: how to choose the right product

- The most important facts in brief

- With a cordless impact driver, you can both screw and drill.

- Impact drilling is also possible thanks to the impact mechanism. You can even work on concrete and stone.

- Torque and speed have to be adjusted to the material, depending on the use, in order to achieve the desired result.

- Different gears can be set depending on the working method. In this way, you can work very sensitively or very quickly.

- Additional functions such as overload protection, a quick-action drill chuck or the Quick System make working with a cordless impact driver easier.

Two functions, one tool

When cordless screwdrivers and drills reach their limits, the best thing for the hobby handyman to do is to use a cordless impact driver. This practical tool combines several functions: you can use it to both screw and drill – and it even has an impact mechanism.

In addition to the conventional screwdriving function, which allows you to tighten screws and nuts, you can activate the impact mechanism when drilling. This is particularly useful for harder materials. With a cordless impact driver, you can not only drill into wood and metal, but also work on stone walls and concrete. In addition, with the cordless version you are not dependent on cables; so you can move freely around the room and still do not have to do without high performance. Only the relatively short battery life and the comparatively high weight limit the possible uses.

The practical all-purpose tool is a practical alternative to conventional drills and cordless screwdrivers and should therefore not be missing from any well-equipped home workshop. Even if impact drills are more expensive than devices with only one function, the universal drills offer various possibilities for home use: from furniture to house construction.

Advantages

- High performance

- Flexible use without cables

- Screwing and drilling possible

- Optional percussion mechanism

- Drills into wood, metal, stone and concrete

Disadvantages

- Comparatively expensive

- Short battery life at maximum power

- High weight

What is a cordless impact driver?

What sounds to the layman like a wild string of technical functions is in fact a universal tool popular with craftsmen that combines screwing and drilling. An essential feature of impact drills is the switchable impact function: in addition to the drilling or rotating movement, the drill head is set into a vibrating movement. Thanks to the percussion mechanism, you can not only drill through “soft” materials such as wood or metal, but also concrete and stone. The impact force is axial, i.e. directed forwards, so that you can penetrate the hard material with the drill. In order not to damage particularly sensitive material or to touch paint, the impact mechanism can be deactivated at any time and the device can be used as a normal drill driver.

A powerful argument: the percussion mechanism

The impact mechanism of a cordless impact driver is mechanically driven: Gears in the gearbox set the drill in motion. You have to generate the propulsion of the machine yourself by applying pressure to the tool. Depending on the material, this requires more force, which is why a hammer drill is recommended instead for particularly hard building materials, in most cases concrete mixtures.

What should be considered when buying a cordless impact driver?

If you want to buy a cordless impact driver, you should pay particular attention to the technical features. First and foremost, the battery capacity and voltage are relevant so that you know how long you can use the device with one charge. Information about the torque, the number of gears and the number of revolutions and impacts provide information about how well the drill driver works and for which areas of application it is suitable. The weight and volume are decisive for your personal comfort during work. Last but not least, you should pay attention to various additional functions that make your work easier and consider appropriate accessories.

The accumulator

The capacity of the rechargeable battery is given in ampere hours. The greater the capacity, the longer you can work at a stretch with one battery charge. High-quality impact drills have between 4.0 and 5.0 ampere hours. For more power-intensive work, the tool should have at least 3.0 amp-hours, as this guarantees a longer runtime. For smaller manual tasks, between 1.5 and 2.5 ampere hours are sufficient. These tools are characterised by their lightweight design and short charging times. The low weight is noticeable in handling; the most powerful devices are the heaviest. Since most drill screwdrivers have lithium-ion batteries, you don’t have to worry about a memory effect. You can recharge the battery as often as you like.

The voltage of the battery indicates the approximate power of the impact drill. For most hobby DIY tools, the voltage is around 18 volts. Smaller, more compact models, on the other hand, have only 12 volts. On the other hand, these drills are lighter and easier to handle. Particularly handy tools even have only about 10 volts. In the professional sector, cordless impact drivers with a voltage of 36 volts are the most common.

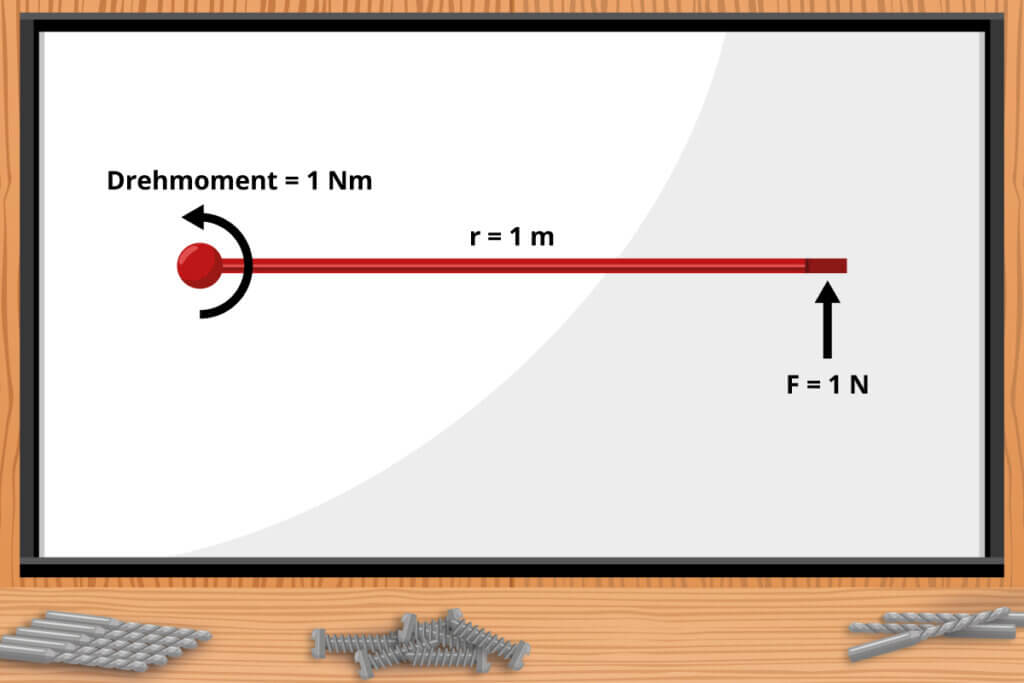

The torque

The Newton metre value for the torque tells you how tightly you can tighten a screw. Most drill drivers have a torque of between 40 and 70 Newton metres. High-quality tools have 85 to 110 newton metres; to do all the work best, 100 newton metres is recommended. A torque limit is practical when you are doing delicate screwdriving work, for example when screwing into wood: you set a torque value that the tool does not exceed.

The gears

When buying a cordless impact driver, you should make sure that the device has a multi-gear transmission. This is highly recommended, but not always the case with inexpensive models.

First gear

The first gear is used for controlled screwing in of screws at a low speed. The low speed produces a higher torque, which in turn allows more force to be exerted on the screw. More force is needed for larger screws, for example. These can quickly become a challenge for the second gear. In addition, you have more control over the drill and the material you are working on.

Second gear

Second gear is used for drilling and impact drilling at a high speed. This setting allows you to make fast progress; for example, if you want to drill several holes in soft material. Because of the low resistance, less force is required. Instead, you can work at a higher speed to penetrate the material faster. For hard material, you should also activate the percussion mechanism.

The speed and the number of strokes

The speed informs you how fast the drill or the drill head rotates. The value is given in revolutions per minute. In higher-priced models, the speed is over 2,000 revolutions per minute. Most conventional devices achieve a value of 1,500 to 1,900 revolutions per minute. You can adjust the speed individually. The higher the diameter of the drill, the lower the speed should be.

The number of strokes provides information about how often the drill strikes forward; however, it does not indicate how powerfully these strokes are executed. The value is also given in revolutions per minute. At the maximum level, i.e. in second gear, most machines achieve between 20,000 and 25,000 revolutions. In first gear, the number of strokes is reduced to around 5,000 to 7,000 revolutions per minute.

Weight and volume

The lighter a cordless impact driver is, the easier it is to handle. Particularly light models weigh around 1.5 kilograms. However, there are also tools that weigh more than twice as much. Increasing weight usually goes hand in hand with better performance. So it comes down to a compromise: 2.0 to 2.5 kilograms is a good middle ground between performance and handling.

Cordless impact drivers can be very loud at the highest setting. Between 80 and 90 decibels are common when working with the tool. This is about as loud as a truck. When used occasionally, the use of a cordless impact driver is harmless to the ears, but prolonged exposure can cause hearing damage. For this reason, you should always wear hearing protection.

The additional functions

When buying a cordless impact driver, you should pay particular attention to the additional functions. The following, exemplary options can make your work easier:

- Overload protection: this protects the motor from overheating and automatically switches it off if it gets too hot.

- Quick system: This system allows you to quickly change drilling and screwing. This is particularly useful if both functions are used frequently.

- Stepless speed control: Thanks to the regulator, you can set the ideal speed for different jobs. This also makes fine adjustment possible.

- Brushless motor: Battery-powered tools without a built-in carbon brush have minimal friction losses. They require less maintenance and are more durable.

- Quick-action drill chuck: No key is needed to change the drill tool inserts. The drill chuck can simply be unscrewed by hand.

- LED light: An integrated light is particularly helpful when assembling furniture or for working in poorly lit rooms. .

The accessories

The following accessories are quite practical:

- Carrying case: A case makes transport easier and is practical for storage. It also offers space for bit sets and spare batteries.

- Carrying strap: Some tools have eyelets to which you can attach a belt or strap. This makes the drill screwdrivers easier to handle.

- Charger: A charger is necessary to charge the battery. Pay attention to the compatibility of the voltage when you buy a replacement battery separately.

Differences to other drilling tools

Although cordless impact drivers are universal tools and are suitable for various work applications, they do not always have to be the first choice for every area of use.

Cordless screwdriver

Cordless screwdrivers are particularly small and handy. As the name suggests, they are devices for screwing. They have no drill chuck and only one gear. Cordless screwdrivers are used for smaller crafts, such as assembling furniture. They replace the classic screwdriver and require hardly any effort of their own. The compact devices are placed on an external charging station for charging and can be operated with one hand.

(Cordless) drill screwdrivers

Conventional drill screwdrivers combine drilling and screwing in one device. They are similar to impact drills, except that they do not have an impact mechanism. Drill screwdrivers also have a chuck and usually two gears. The device can replace the classic drill and is particularly practical when work requires screwing and drilling. Drill screwdrivers are not suitable for particularly hard materials because they lack an impact function, but they are sufficient for wood and metal. The rechargeable battery version allows for particularly flexible use.

Hammer drill

Hammer drills are the first choice for solid surfaces or chiselling work. The tools have a powerful percussion mechanism: the hammer is flung in the direction of the drill, similar to an impact drill. This axial movement has a much higher impact force than that of a cordless impact driver. The impact mechanism is driven into the wall almost independently, which is why hardly any effort is required on your part. You only need to concentrate on applying the hammer drill at the right angle and maintaining control while drilling. A hammer drill can be used to work on various hard materials such as reinforced concrete. It can also be used for chiselling work. If you want to remove tiles or an entire wall, for example, place a chisel on the tool head instead of a drill and deactivate the rotary movement. The forward-facing percussive movement takes care of the rest.

2,022 reviews

2,022 reviews