Angle grinder purchasing advice: how to choose the right product

- What You Need to Know

- Angle grinders are tools with a high-speed rotating grinding wheel.

- The exchangeable disc makes them suitable for many applications and materials.

- Standard diameters for the discs are 115, 125 and 230 millimetres.

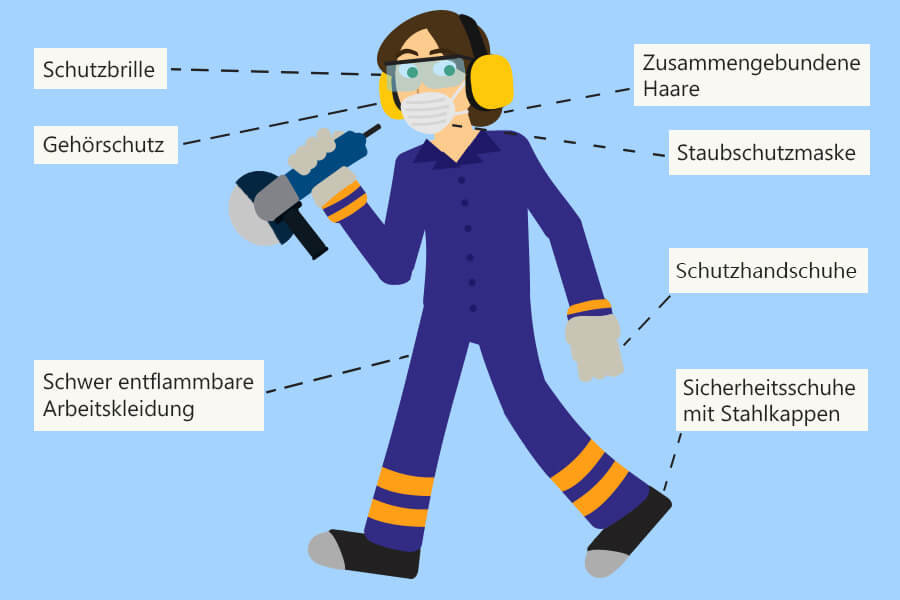

- The risk of injury is high, users must always take protective measures when using them.

What are angle grinders?

An angle grinder belongs in every well-equipped DIY workshop. These versatile power tools are not only suitable for cutting through hard materials, but also for cleaning up welds, derusting, polishing, removing varnish and, as the name suggests, grinding and roughing. They are only suitable to a limited extent for working on wood, as it can carbonise due to the great heat generated.

In 1954, the company Ackermann & Schmitt launched the first high-speed angle grinder under the brand name Flex. The brand name has become established as a generic name. In German and in some other languages, “Flex” stands for angle grinder in general, regardless of the manufacturer.

Angle grinders rotate a (cutting) disc at an extremely high speed, reaching up to 13,300 revolutions per minute and a cutting speed of 80 metres per second. This allows them to cut through solid materials such as metal, stone and concrete with ease. Since the discs have a certain elasticity, they do not break even when slightly tilted. This makes angle grinders suitable for working without a guide rail.

To withstand the high centrifugal forces caused by the extremely fast rotation of the discs, they are reinforced with fabric inserts. The elasticity of the synthetic resin from which the discs are made also contributes to their resilience.

Caution! Never rough grind with cut-off wheels.

The stabilising glass fibre fabric is only attached to the outside of conventional cut-off wheels. It would wear out quickly during rough grinding. Without the reinforcing fabric, the disc can easily burst. Therefore, only special discs, so-called flap discs or roughing discs, may be used for this purpose.

Apart from the intended use, the type of disc depends above all on the material of the material. There are special cutting discs for stone, for metal and for wood. However, discs made of diamond-coated steel are also sold as universal discs, as they can cope with almost all materials thanks to their high hardness.

Ordinary angle grinders for workshop use are always electrically powered. They are either corded devices or cordless angle grinders. Large, petrol-powered angle grinders are used in road construction or track construction. Here, however, we focus on electric angle grinders for home and workshop use.

Types of angle grinders

The market for angle grinders is relatively differentiated, with devices available for very different purposes. From the battery-powered mini angle grinder for fine metal work to the heavy two-handed device with a large disc diameter that can also eat through bulky stone slabs and concrete floors, a wide range of different devices is available to the craftsman.

Mini angle grinders

The dwarfs among the angle grinders have cutting discs with a diameter of up to 115 millimetres. They are very handy. Thanks to the lower weight, users do not tire as quickly as with larger angle grinders. If the material being worked on is not too thick, they are a good alternative to larger devices. For jobs where accuracy is most important, the small ones are even the better choice.

Pro Points

- Very precise work possible

- Can be used with little effort

- Not particularly heavy even with battery

- Inexpensive

Drawbacks

- Small cutting depth

- Too little power for roughing large areas

One-hand angle grinder

With a cutting disc diameter of 125 millimetres and more, common one-hand angle grinders are true universalists. They are still light and compact enough to allow effortless work, yet they have enough power and a sufficiently large cut-off wheel diameter to be able to work on coarser materials. Despite their name, the user should always use two hands whenever possible. The smaller the cut-off wheels on a tool, the greater the speed of rotation, as smaller wheels require more revolutions to cover the same cutting distance.

Pro Points

- Versatile

- Good price-performance ratio

Wide choice of discs

Drawbacks

- Not powerful enough for rough work

Two-hand angle grinder

Two-hand angle grinders are much more difficult to use than one-hand angle grinders. They are comparatively large and heavy, which means that they require some skill to apply cleanly. It is easier with a soft start, i.e. a slow start function, which is one of the most important features of the large two-handers.

Since they weigh up to seven kilograms, working with these tools can be very power-consuming. However, they drive their sanding discs with a power of 1,000 watts and more. So the two-handed sanding witches have a lot of power. And they need it. With a disc diameter of usually 230 millimetres, they achieve a cutting depth of up to 7 centimetres. These are tools for the rough, which can also be used to work on solid stone and concrete slabs.

Pro Points

- Powerful material removal

- Large cutting depth

Drawbacks

- High weight

- Relatively expensive

- Difficult to apply accurately

Corded angle grinders

Corded angle grinders are less expensive than battery-powered devices with comparable performance data. However, they are less flexible in use because the cable restricts the user’s freedom of movement. This is certainly true for mini cut-off grinders and smaller one-handers. The extra weight of the battery would make larger cordless tools much more unwieldy than any cord ever could, so angle grinders over a certain size are pretty much always corded.

Pro Points

- Relatively low weight

- Good price-performance ratio

- Available with large disc diameters

Drawbacks

- The cable is in the way when working

- Can’t be used without a power connection

Cordless angle grinder

Just a few years ago, cordless angle grinders were not considered very practical. The power of the rechargeable batteries of the time was simply too low. Either they did not bring enough power to the grinding wheel or they did not last long enough. In the meantime, however, there are high-quality devices that no longer have these problems. However, all cordless angle grinders weigh about 500 grams more than comparable corded models.

Buyers of cordless angle grinders should pay attention to the suitability for quick chargers, because nothing is more annoying than having to stop work for the day because the battery is empty and the tool has to be put on the charging station overnight. Quick chargers are either included or can be purchased as optional accessories.

Pro Points

- No annoying cable when working

- Can be used without a power connection

- Performance comparable to one-hand angle grinders

Drawbacks

- More expensive than corded tools

- Higher weight

- Only small and medium diameters available

Discs for angle grinders

Discs for angle grinders have to withstand enormous loads. They are made of special synthetic resin compounds. Thanks to a certain flexibility and reinforcement with glass fibre, they do not burst under the extreme centrifugal forces to which they are subjected during use.

Since synthetic resin loses flexibility and becomes brittle with age, all cut-off wheels have an expiry date printed directly on the wheel. For safety reasons, the discs must not be used under any circumstances once they have passed this date.

Because of the limited shelf life, it does not make sense to buy cut-off wheels in stock. In addition, buyers should be careful not to be sold discs that they will no longer be able to use in a few months.

The right disc for every application

An important distinguishing feature of cut-off wheels is their thickness. Thinner discs are better suited for precise work, thicker discs wear out more slowly.

Suitable discs are available for different materials and working techniques. Discs must only be used for their intended purpose. Using them for work for which they are not suitable is risky and can lead to dangerous accidents.

Ordinary cut-off wheels must never be used for roughing. The glass fibre reinforcement of cut-off wheels wears off quickly and they burst. This is extremely dangerous, because the high rotational speed of a cut-off wheel turns breaking-off parts into projectiles that can cause serious injuries.

The table provides an overview of the available discs and other attachments for angle grinders.

| Attachment | Use | Material |

| Metal cutting disc | Cutting of metal | High-grade corundum |

| Stone cutting disc | Cutting stone | Silicon carbide |

| Wood cutting disc | Cutting wood | Steel |

| Chain saw blade | Felling small trees, woodworking | Steel |

| Diamond cutting disc | Cutting particularly hard materials such as ceramics and concrete | Diamond-studded steel |

| Roughing wheel | Breaking edges, cleaning weld seams, grinding, roughing | Stainless corundum |

| Flap disc | Grinding and polishing | Glass-fibre reinforced polyester |

| Grinding disc | Grinding, derusting, paint removal | Glass-fibre reinforced polyester |

| Wire cup brush | Derusting, paint removal, cleaning | Steel wire |

| Wire round brush | Derusting, paint removal, cleaning | Steel wire |

| Joint milling | Milling out joints | Metal |

| Polishing disc | Polishing | Abrasive fleece |

What you should look for when buying

What should buyers of an angle grinder look out for? We explain which product features are important and which accessories are useful.

Disc diameter

The wheel diameter determines the cutting depth. The larger it is, the thicker the materials that can be cut with the angle grinder. With small angle grinders, the diameter of the cutting disc is only 115 millimetres and they usually have a cutting depth of less than 3.0 centimetres. Units with a disc diameter of 125 millimetres have a cutting depth of around 3.5 centimetres. With a disc diameter of 150 millimetres, it is already 4.5 centimetres. The largest cut-off machines with a wheel diameter of 230 millimetres achieve a cutting depth of around 7.0 centimetres.

However, these values only apply to new cut-off wheels. Used cut-off wheels lose diameter due to wear and then also have a shallower depth of cut.

Performance

The power of a cut-off machine is measured by the wattage of the motor. Battery-powered machines are at the lower end of the power scale, while common and inexpensive single-handed models for corded operation have between 750 and 850 watts. These machines usually weigh around two kilograms. They are therefore light enough for longer working sessions.

If you need the angle grinder for rough work, you should look for machines with at least 1,000 watts. These, however, weigh five kilograms and more. They therefore have a weight that is quite burdensome when working for longer periods.

Grinding and roughing work puts more strain on the motor than cutting work, as it has to constantly fight against the high grinding friction. If you need an angle grinder primarily for this purpose, you should choose one with the highest possible power.

Idle speed

The higher the speed of an angle grinder, the faster it cuts through a workpiece or the faster it removes layers with the grinding wheel. Unlike drills, the rotation speed of angle grinders is fixed. Speeds between 11,000 and 14,000 revolutions per minute are common. They should not be much lower, otherwise the work progresses agonisingly slowly.

The larger the disc diameter, the faster the sawing movement at a constant rotational speed. Conversely, this means that angle grinders with a large wheel diameter can achieve a sufficient cutting speed even with a low number of revolutions. However, even large two-handed angle grinders should not have less than 6,000 revolutions per minute.

Soft start

An angle grinder with soft start does not start immediately at full speed, which makes starting much easier, especially with large angle grinders. This function is therefore almost a must for two-handed devices with a wheel diameter of 230 millimetres, but smaller grinding wizards can manage well without it. On mini angle grinders with wheel diameters of less than 115 millimetres, a soft start is completely unnecessary.

Restart protection

Because of their high speed, angle grinders pose a considerable risk of injury. One risk is the automatic start after an interruption in the power connection. The units should be designed in such a way that this cannot happen. When the power is restored, they must be switched off regardless of the operating state when the power was interrupted. Manufacturers solve this either by ensuring that the units are only on as long as a switch is pressed, or by using power-on buttons that automatically release their lock without power.

Cable length

The length of the connecting cable is an issue that many buyers of cord-cutters do not worry about. But if the cable turns out to be too short during the first few uses, that is very annoying. A usable cable for power tools should have a minimum length of two metres. Even longer cables are better. A cable length of four metres leaves nothing to be desired. If you are even further away from the next socket, you can help yourself with an extension cable.

Cutting stand

A cutting stand is indispensable for precise cuts with the angle grinder. The tool and workpiece are clamped in place so that the cut is made at exactly the right angle and in the intended position. Cutting stands should be solid in order to be stable.

A cutting stand is hardly ever part of the accessories supplied. Buyers should make sure that the stand fits their tool. When buying in a DIY shop or tool shop, it is advisable to take your own angle grinder with you and ask for advice from an employee. When buying online, the only option is often to read customer reviews thoroughly.

Extraction bonnet

When working with an angle grinder, a considerable amount of fine dust can be produced and swirl in the air. Grinding dust is not only a nuisance, but also harmful to health. The extraction bonnet connects to a hoover and picks it up directly at the unit, so it has no chance of spreading around the room. Although the extraction bonnet reduces dust exposure considerably, it does not stop it completely. Therefore, the worker should still not do without suitable respiratory protection.

Case

A case for the Flex is the right accessory for all those who like to store their tools neatly. It is ideal if the case has space for accessories such as cutting discs, so that everything necessary for using the angle grinder is immediately at hand. Inexpensive cases are made entirely of cast plastic, while high-quality versions have aluminium profile strips and an inner lining of foam.

A case is often included in the scope of delivery for angle grinders in the higher price segment. If not, the flex can also be stored well in another commercially available tool case. Cube or nubbed foam inside the case ensures that the tool is stored safely and shockproof.

Use and safety

Its fast-spinning disc makes the angle grinder one of the most dangerous tools in the DIYer’s arsenal. The hot sparks produced when working on metal pose an additional risk. They can injure the sensitive cornea of the eyes and set fire to unsuitable clothing.

Eye protection

Suitable eye protection is an absolute prerequisite when working with an angle grinder, especially when working with metal. Extremely hot abrasive chips can otherwise burn into the cornea of the eye, resulting in emergency ophthalmological treatment and lifelong visual damage in the worst case.

Hearing protection

An angle grinder can reach a volume of up to 100 decibels. That is louder than the take-off of a Boeing 747 from 500 metres away. Just a few minutes of working with this level of noise can cause permanent hearing damage. As always when working with loud equipment, suitable hearing protection is therefore an absolute must.

Dust protection

Working with an angle grinder produces a lot of fine dust that should not be inhaled. As a safety measure, a tight-fitting dust mask that covers both nose and mouth must therefore be worn.

To prevent so much dust from being distributed in the room in the first place, it is advisable to use an extraction bonnet for the angle grinder. Moving workpieces can be processed outdoors, where the dust is quickly dispersed. However, neither the dust extraction bonnet nor working outdoors is a substitute for wearing a dust mask.

Safety clothing

Suitable clothing for working with an angle grinder must meet two requirements: It must not fit so loosely that it gets caught in the rotating disc, and it must not catch fire from flying sparks. Wool and man-made fibre is far too flammable and must not be worn when flexing. Special protective clothing made of flame-retardant cotton is strongly recommended.

Tie up long hair

It is not only clothing that runs the risk of getting caught in the angle grinder, but also hair over a certain length. Long hair should therefore be tied behind the head. A cap helps to hold back medium-length hair that is too short to tie up.

Safety shoes

Anyone working on large stone or metal objects should wear safety shoes with steel toecaps. This protects the feet from detached pieces falling to the ground.

Avoid worn and old discs

One danger when working with angle grinders is splintering discs. The fragments are thrown away at high speed and can cause injuries and damage. Workers should therefore no longer use visibly damaged or heavily worn discs.

Flex discs that have passed their sell-by date are also no longer safe, because the synthetic resin material used becomes brittle and fragile over time.

Only use suitable discs

A maximum number of revolutions per minute is printed on each disc for the cut-off machine. If the tool rotates faster than the disc can withstand, it may shatter. Therefore, the maximum number of revolutions of the disc should be higher than or equal to the number of revolutions of the angle grinder.

It is also important that the disc fits the intended use. Roughing with cut-off wheels is particularly dangerous. Roughing discs are much thicker than cut-off discs to withstand the high lateral load.

Never work without a protective bonnet

Every angle grinder comes with a protective bonnet. It ensures that the tool is shielded from the user. It keeps the user’s clothing and body away from the rotating disc. The protective bonnet also directs sparks and fine particles away from the user. Without the protective bonnet, the risk of hand injury is extremely high, so it should never be removed.

Do not work on the moving object

If the material comes loose when working with the Flex, it can be thrown across the room with great force. If it slips, there is a risk of the worker slipping with the tool and injuring himself or damaging nearby objects. Therefore, make sure that the material is firmly installed or securely clamped.

Caution when changing discs

Angle grinder discs should only be changed on the unplugged tool. The rotation must have stopped before the user touches the disc. Immediately after use, the discs are usually very hot. To avoid burns, they should be given time to cool down before changing.

329 reviews

329 reviews