Bike pump purchasing advice: how to choose the right product

- What You Need to Know

- Bike pumps come in three varieties that vary greatly in terms of performance, ease of use and size: Floor pumps, foot pumps and hand pumps.

- One of the most important features of a bike pump is its performance in bar.

- Road bikes need a high air pressure, which a simple hand pump often cannot achieve.

- Before buying, make sure the pump is compatible with your bike’s valve.

For a smooth riding experience

If you own a bicycle, you need a pump. Be it a hand pump included with the bike or an expensive floor pump bought separately, everyone needs to fill their tyres with air sooner or later. You don’t have to be an experienced bicycle hobbyist to do this, just connect the pump to the tube valve and pump. The process is very intuitive regardless of the type of pump. This will keep your tyres full and you can simply ride on or off.

Bike pumps are piston pumps and basically all work in the same way: When you pull up, the inlet valve opens and air flows into the cylinder-shaped pump interior. As soon as you push the handle down, the inlet valve closes and the outlet valve opens. The air is thus forced out and passes through the valve into the tyre tube. The maximum pressure at which this happens depends on the type of pump and the model.

The design of bike pumps is also strongly dependent on the type of pump. After all, hand pumps, floor pumps and foot pumps look very different, even if their mode of operation is the same. However, all bike pumps have one thing in common: they are operated by a handle or a control surface – hand and floor pumps have handles, while foot pumps have pedals. Furthermore, the majority of the body of pumps is a cylindrical rod containing a piston that enables pumping. Last but not least, all bike pumps have a connection to the valve of the bike tube. This connection is either on a flexible tube or the pump head.

The type of bicycle pump: performance, comfort or transport?

Manually operated bike pumps are divided into three types: Floor pumps, hand pumps and foot pumps. They vary in performance, dimensions, weight and operation. Although they are all suitable for pumping, it is not that easy. A bulky floor pump is inconvenient for a long bike ride. On the other hand, pumping with a hand pump can take forever and be very tiring. In general, regular riders are advised to buy two pumps, one for home and one for on the road.

Floor pumps: High power, short duration

Floor pumps have a base on which a cylindrical body is mounted. At the top is a T-handle, which you use to pull the pump up and push it down. At the bottom end is a hose, the connector of which is connected to the hose valve. Usually such pumps are 30 to 65 centimetres tall and weigh between 1.5 and 2.5 kilograms. This makes them the largest and heaviest models. They are therefore not particularly suitable for taking with you.

On the other hand, floor pumps are the most powerful. This means that they reach the highest pressure. Depending on the model, floor pumps generate a maximum pressure of 8 to 16 bar. For most models, the upper performance limit is 11 bar. They are particularly recommended for road bike owners, as such bikes require the highest tyre pressure. You can usually read the pressure on a pressure gauge, which most models are equipped with. They also pump quickly and are easy to use. However, they are on average somewhat more expensive than hand or foot pumps.

Pro points

- Easy to operate

- Fast pumping

- High performance

- Pressure gauge usually available

- Flexible hose

Drawbacks

- Large

- Hard

- Expensive

Foot pumps: gentle on the back and comfortable

Foot pumps have a pedal that sets the cylinders in motion. If you do not put pressure on the pedal with your foot, it pulls up and air is let into the inside of the pump. When you press down on the foot pedal, the air is forced out. In addition to the pedal and the cylinder, foot pumps are equipped with a pressure gauge and a flexible hose. You can often clamp the pumps down when compressed for compact storage and easy transport. Similar to hand pumps, they are rarely taller than 30 centimetres, but weigh a little more at 1 to 2 kilograms.

The operation of foot pumps is simple and intuitive. It is not as strenuous as with hand pumps, but also not as effortless as with floor pumps. It is true that you need a little longer to pump with floor pumps. If you have back problems, however, they are optimal because, unlike the other pumps, they allow you to maintain an upright posture while pushing. For users without back problems, foot pumps are also comfortable because you do not have to bend down to operate them. Their maximum output is usually about seven bar.

Pro points

- Intuitive

- Compact

- Easy on the back

- Comfortable

- Flexible hose

Drawbacks

- Long pumping time

- Low output

Hand pumps: Practical and inexpensive

Hand pumps resemble short rods. At one end is the handle and at the other the head with the valve connection. These pumps are operated by short and quick pulling and pushing movements. With a length of 15 to 25 centimetres and a weight of 150 to 200 grams, they are the smallest and lightest bike pumps. That is why they are best suited for long tours and are also called mini pumps. Bicycles often have a bracket to which a hand pump can be attached.

However, they are also the simplest or least functional pumps. There is hardly ever a pressure gauge. It is true that pumping is very simple and intuitive. On the other hand, it is the most strenuous compared to the other pumps. This is not only because they use smaller, weaker muscle groups compared to the other bike pumps, but also because a hand pump simply takes you the longest. Their maximum pressure output is usually eight bar. This is not as much as with floor pumps, but the pressure is sufficient for most types of bikes and tyres. Last but not least, they are usually very inexpensive.

Pro points

- Small

- Easy

- Inexpensive

- Intuitive

Drawbacks

- Limited range of functions

- Effortful operation

- Long pumping time

- Often inflexible head

Mini hand pumps: combination of hand and floor pumps

Last but not least, there are floor pumps in small versions. These are mini hand pumps. They are very similar in size to hand pumps and are therefore perfect to take with you, as they usually fit into holders for hand pumps. However, you have to bend down a bit more to operate them, which is detrimental to their user comfort. Such models are particularly suitable for long tours with the road bike, as they are light and compact, but have the performance of floor pumps and can also fill a road bike tyre with sufficient pressure. Due to their small size, however, their pumping volume is considerably smaller than that of conventional floor pumps. Accordingly, pumping takes longer than with normal floor pumps. They can usually be held in the hand and operated like hand pumps.

Pro points

- Compact

- Easy

- High maximum pressure

- Can also be used as hand pumps

Drawbacks

- More difficult to operate than floor pumps

- Longer pumping time than floor pumps

The bicycle valve connections

The inner tubes of bicycle tyres can be equipped with three different types of valves. Each of these valves is known by numerous names, but most commonly we talk about Dunlop, Sclaverand and Schrader valves. These vary in two respects: Firstly, they are shaped differently and thus each requires a suitable connection. Secondly, they have different permissible maximum pressures.

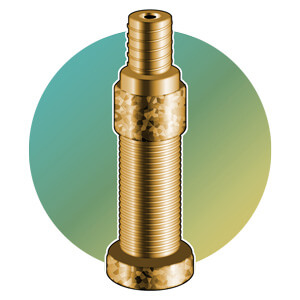

Dunlop valve

Dunlop valveThe Dunlop valve, named after John Boyd Dunlop, is the most common type on bicycles and is therefore sometimes called the “standard valve”. It is mainly used on bicycles for everyday use, such as city or trekking bikes. Its maximum pressure is six bar. Provided your pump has a suitable connection, a hand or foot pump should also be able to inflate a tyre with a Dunlop valve. Usually these valves have a plastic or metal cap that screws onto the thread.

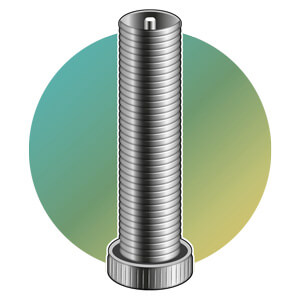

Schrader valve

Shrader valveSchrader valves are mainly found on cars as well as mountain bikes and are therefore also known as car or MTB valves. These valves can withstand pressures of up to ten bar, although such high pressures are hardly necessary on mountain bikes. Note that these valves only open when the pump is put on and taken off. Some air is always lost in the process. The two processes should therefore take place quickly. Thanks to their valve relationship to cars, you can even pump up your mountain bike with a Schrader valve at the petrol station.

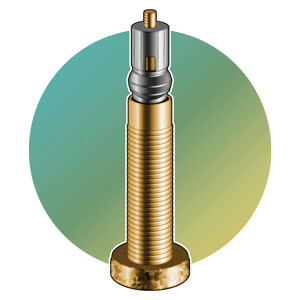

Sclaverand valve

Sclaverand valveThe narrow Sclaverand valves were once only found on racing bikes and are therefore often called racing bike valves. Today, however, you will find them not only on racing bikes but also on some mountain bikes and trekking bikes. To pump, first remove the valve cap. Then screw on the knurled nut as far as it will go. Now you can put the valve connection of the pump straight on and start pumping. Sclaverand valves have the highest permissible maximum pressure of about 15 bar.

Other buying criteria

Not only does each type of bicycle pump have its own special features, but pumps also differ from model to model. Before buying, pay close attention to features such as performance, pump volume and equipment.

Maximum pressure of the tyre tube

The maximum capacity of a pump is stated in the product information. How much pressure your bicycle tyre or inner tube allows or requires depends on the tyre width and the weight of the rider. You should therefore be aware of this before buying a pump. All types of pumps can cover the lower end of the pressure spectrum, about 2.0 to 5.0 bar. Above 7 bar, you need to be more specific about the type of pump and the model.

The higher the rider’s weight, the higher the tyre pressure must be. Except for racing bikes, where you lean forward a lot and shift a large part of your weight onto the steering wheel and thus the front tyre, it is recommended that the pressure on the rear tyre is about 0.5 bar higher, if the tyre manufacturer’s specifications allow for this.

Influence of tyre width and bicycle type

Probably the most decisive aspect for the appropriate pressure is the tyre width. The type of bicycle plays a role in that each type of bicycle usually has certain tyre widths. Racing bikes, for example, have the narrowest tyres, while mountain bike tyres are wider. The German Bicycle Club (Allgemeine Deutsche Fahrrad-Club e. V.) provides guidelines for determining the appropriate tyre pressure. It should be noted that the maximum permissible pressure is indicated on the tyre and must not be exceeded. These values are based on a body weight of 75 kilograms. For each kilogram more or less, including luggage, the pressure can be increased or decreased by about 1 percent:

| Tyre width in millimetres | Air pressure in bar |

| 20 | 9,0 |

| 23 | 8,0 |

| 25 | 7,0 |

| 28 | 6,0 |

| 30 | 5,5 |

| 32 | 5,0 |

| 35–37 | 4,5 |

| 40–42 | 4,0 |

| 44–47 | 3,5 |

| 50 | 3,0 |

| 54 | 2,5 |

| 57 | 2,2 |

| 60 | 2,0 |

Road bikes usually have a tyre width of 20 to 28 millimetres, as they focus on low resistance and are designed for flat riding surfaces. Trekking and city bikes are usually fitted with 30- to 50-millimetre tyres, as they need to ride on both smooth surfaces and jerky curbs. Mountain bikes are designed for uneven terrain and thus require the widest tyres and the lowest pressure. The shock-absorbing effect of this tyre-width-pressure combination benefits you especially when riding downhill. Last but not least, there are the so-called “fatbikes”. These are a type of mountain bike with extremely wide tyres. Their pressure should be between 0.5 and 1.0 bar.

How does the pressure affect the riding behaviour?

In addition to the tube pressure, the tyre is also decisive for the bike’s handling. Depending on the tyre profile or width, a different pedalling performance is required. For example, a bicycle with a wide tyre that has large lugs requires more pedalling power on a flat riding surface than a narrow, flat tyre. Pressure also has a strong effect on the tube’s riding experience:

| Characteristics | Tyre pressure |

|---|---|

| Low resistance on a flat surface | High tyre pressure |

| Low resistance on a funeven surface | Low tyre pressure |

| Less wear on the tyre tread | High tyre pressure |

| More resistance when pedalling | Low tyre pressure |

| Less susceptibility to punctures | High tyre pressure |

| Higher shock absorption | Low tyre pressure |

Pumping time

The volume of air that a bike pump can squeeze out with one stroke is decisive for the pumping speed. The size of the pump plays an important role: a large floor pump can pump out more air with one stroke than a small hand pump. As a rule, the floor pump has the highest pumping speed, while a hand pump takes the longest. The foot pump takes the middle place. Equally relevant for the pumping time is the hose volume. The volume is given in pumping strokes per bar. However, precise information on this is seldom to be found.

To reach a pressure of 4 bar, a floor pump needs between 25 and 30 strokes, depending on the model. A foot pump, on the other hand, requires 100 to 150 strokes. A hand pump requires an athletic performance of 200 or even more strokes.

Power requirement

The most important feature of a bike pump that provides information about the amount of force required is the diameter of the piston. The wider the piston or the cylindrical tube in which it is located, the more resistance is generated, i.e. the more power you need for one stroke. A narrow pump is therefore easier to operate than a wide pump. A narrow and large floor pump therefore requires the least amount of energy, as it offers both low resistance and a high pumping volume.

Equipment

The features of a bike pump depend on the type and model. Floor pumps are usually more extensively equipped than hand pumps. One important feature, for example, is the pump head. Floor pumps and foot pumps usually have a hose, which makes them more flexible and easier to use. The often fixed head of hand pumps makes pumping more complicated, as the pump has to be held and operated directly at the valve.

The pump head must also fit the tube valve. Many bike pumps can be connected to all three valve types. If this is not the case, it is recommended to pay attention to the manufacturer’s specifications as well as the valve type of your bike and to match them if necessary. In addition, an attachment for inflating balls is often included in the scope of delivery.

The usually available locking lever is also indispensable. The lever on the pump head is operated to fix it to the valve. This way, you do not have to press the pump continuously against the valve and can concentrate on pumping.

Last but not least, a pressure gauge is an important extra. It shows you the tyre pressure. This makes it easier for you to judge whether the tyre is inflated. While floor and foot pumps are usually equipped with a pressure gauge or pressure indicator, this is rarely the case with hand pumps.

Size and weight

The size of a pump not only affects its pumping volume. It plays a particularly important role in transport. You probably don’t want to carry a large floor pump on a long tour. That’s why hand pumps that fit in your backpack or are mounted on your bike are usually used when you’re on the road.

Weight also has an impact on transport. Floor and foot pumps often weigh a few kilograms, which is a lot compared to hand pumps weighing 100 to 200 grams. However, for pumps that are mainly used at home, a heavy weight is not a drawback.

Material

Bike pumps are made of either plastic or metal. Both materials are often used. The material has a strong influence on the weight of the pump. Plastic, for example, is lighter than metal. For this reason, many hand pumps are mainly made of plastic, as they are designed for transport and should be as light as possible. In addition, they are not subjected to particularly strong strokes during operation. However, plastic pumps are more susceptible to damage because the material is not very robust.

Floor and foot pumps usually have to withstand the entire body weight of the user when pumping. Therefore, they should be much more robust than hand pumps. Metal is therefore the more suitable material for their manufacture. In addition, these pumps benefit from a higher weight. It makes them more stable and thus reduces the likelihood of them shifting or tipping over during pumping.

10,089 reviews

10,089 reviews